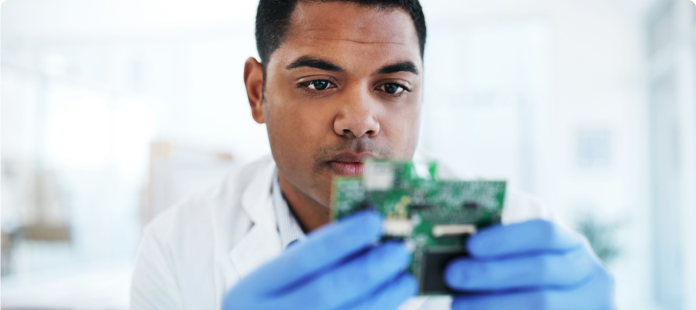

At IoTronix, we offer comprehensive manufacturing and assembly solutions to meet the unique demands of diverse industries. From high-quality PCB assembly to complete box-build systems, our tailored processes ensure efficiency, precision, and reliability at every stage. With stringent quality control measures and advanced technologies, we deliver products that consistently exceed expectations.

Manufacturing process

IoTronix’s manufacturing process integrates cutting-edge SMT (Surface Mount Technology), automated assembly, and backend operations to ensure seamless production. Every step, from PCB loading and soldering to assembly and packaging, is optimized for accuracy and efficiency.

Box-build assembly

We provide full box-build services, including sub-assembly, PCBA mounting, functional testing, and final packaging. IoTronix ensures high-quality builds with detailed inspections for components, housing, and final units, delivering ready-to-use products for our clients.

Test solutions

Testing is integral to our process. IoTronix performs 100% functional testing, visual inspections, and automated quality checks, covering areas like soldering quality, product performance, and component functionality. From RF calibration to LCD, camera, and power tests, we ensure products meet exacting standards.

Quality assurance

IoTronix maintains rigorous quality control at every stage, from solder paste inspection to cosmetic checks of finished goods. Processes like X-ray inspections, underfill checks, and flatness evaluations ensure consistent product excellence.

Our solutions are designed to empower businesses by reducing time-to-market and ensuring their products meet the highest standards for performance, reliability, and scalability.